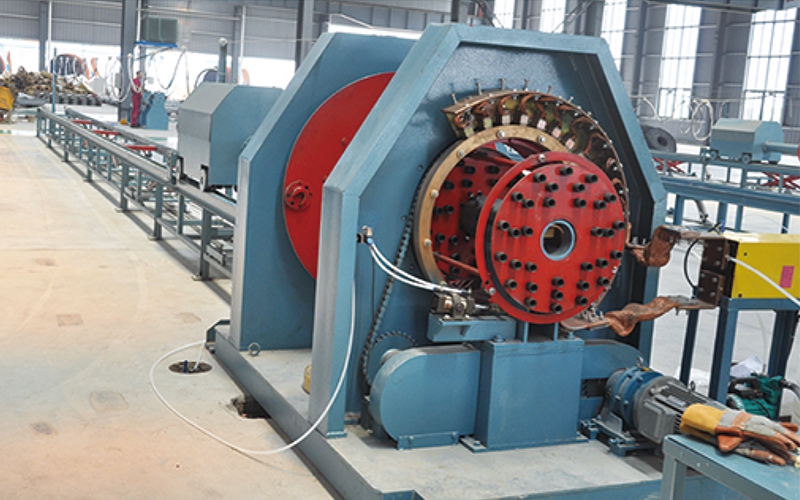

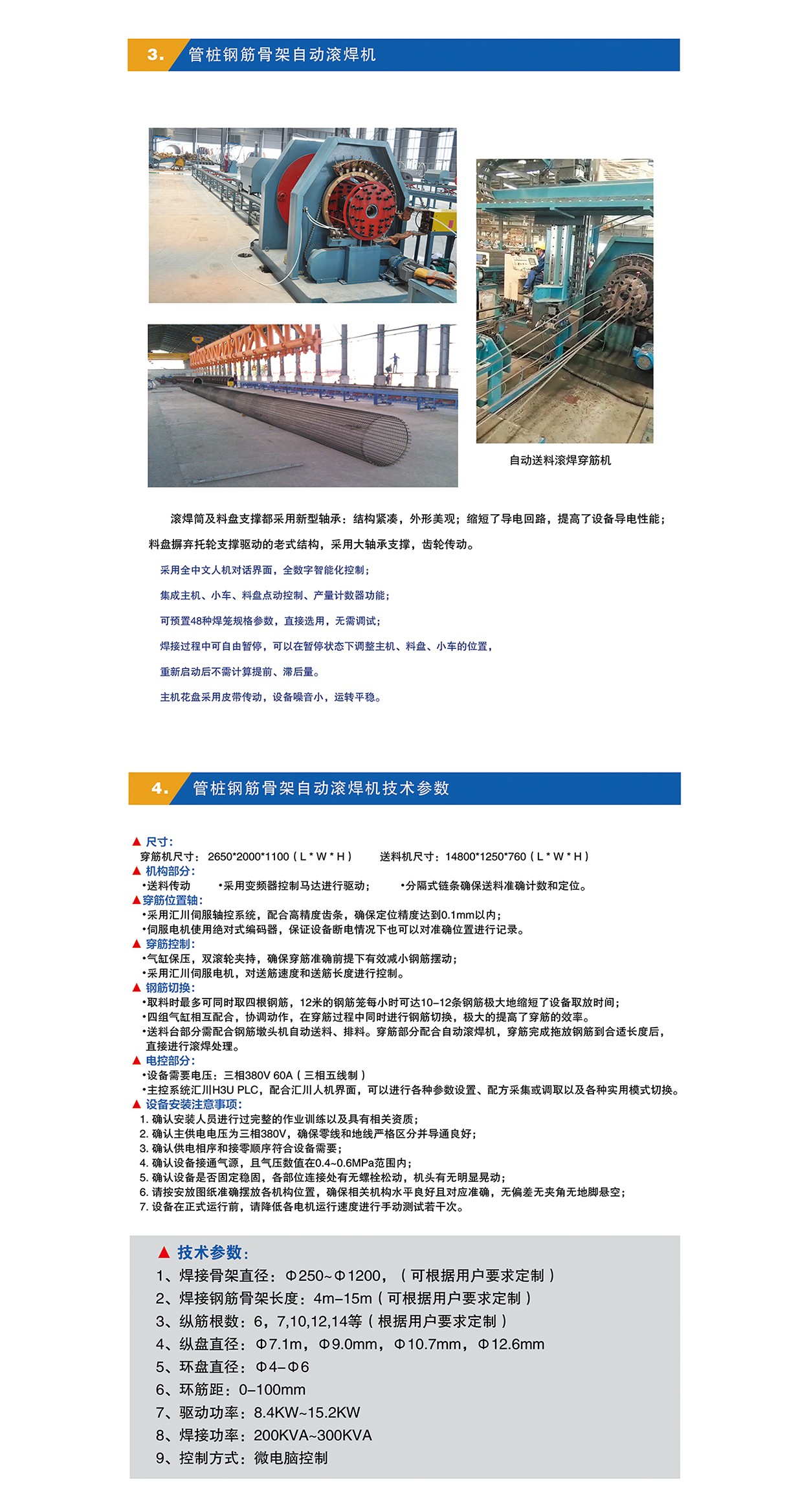

Automatic rolling welding machine for steel reinforcement framework of pipe piles

The roller welding cylinder and material tray support both adopt new bearings: compact structure and beautiful appearance; Shortened the conductive circuit and improved the conductivity performance of the equipment; The material tray abandons the old-fashioned structure of wheel support drive and adopts large bearing support and gear transmission.

Adopting a fully Chinese human-machine dialogue interface and fully digital intelligent control;

Integrated host, trolley, material inventory control, and output counter functions;

48 preset welding cage specifications and parameters can be directly selected without the need for debugging;

During the welding process, it is possible to freely pause and adjust the position of the host, material tray, and trolley in the paused state. After restarting, there is no need to calculate the advance or lag amount;

The host flower tray adopts belt transmission, which reduces equipment noise and ensures smooth operation.

24-Hour Hour Hotline:

1805260977715301436678