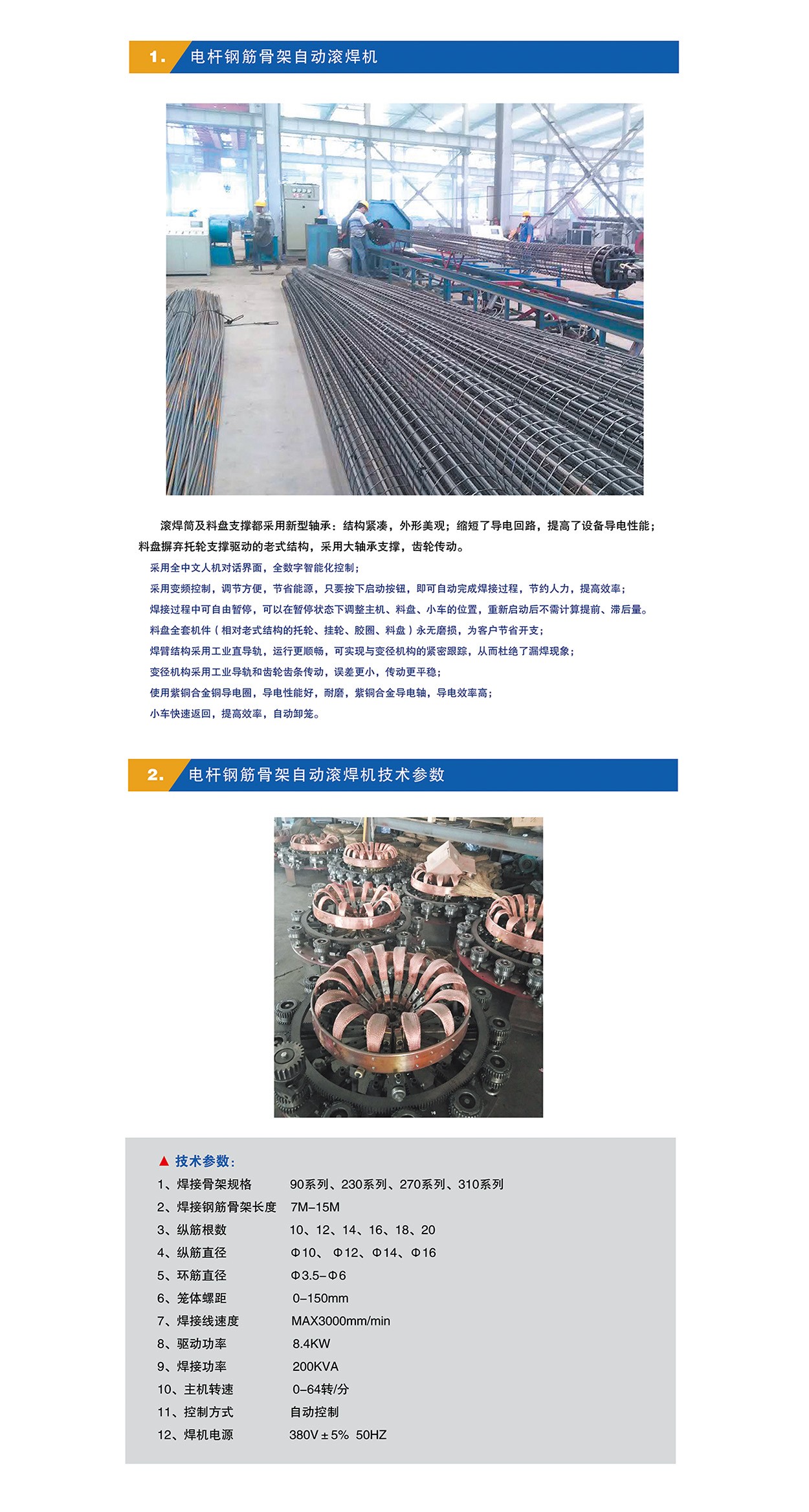

Automatic hob-welding machine for steel bar frame of electric pole

New bearings are used for the welding cylinder and tray support: compact structure and beautiful appearance; The conductive circuit is shortened and the conductive property of the equipment is improved. The old structure of the plate driven by the support wheel is abandoned, and the large bearing support is adopted and the gear is driven. <br>

Full Chinese man-machine dialogue interface, full digital intelligent control; <br>

Adopt frequency conversion control, easy adjustment, save energy, as long as press the start button, you can automatically complete the welding process, save manpower, improve efficiency; <br>

The welding process can be freely suspended, you can adjust the position of the host, the tray and the trolley in the suspended state, and do not need to calculate the advance and lag amount after restarting. <br>

The whole set of parts of the tray (relative to the old structure of the supporting wheel, hanging wheel, rubber ring, tray) is never damaged, saving costs for customers; <br>

The welding arm structure adopts industrial straight guide rail, which runs more smoothly, and can realize the close tracking with the reducing mechanism, so as to eliminate the welding phenomenon; <br>

The reducer adopts industrial guide rail and rack and pinion drive, with less error and more stable transmission; <br>

The use of copper alloy copper conductive ring, good conductive performance, wear resistance, copper alloy conductive shaft, high conductive efficiency; <br>

Quick car return, improve efficiency, automatic unloading cage.

24-Hour Hour Hotline:

1805260977715301436678